Within the challenging realm of building, capacity and accomplishment are key. To satisfy these requirements, latest assembly apparatuses have developed to provide exceptional capability and trustworthiness. Contemporary superior building equipment options are equipped with progressive features increasing effectiveness and curbing environmental effects. Encompassing durable scoopers and lifters to agile winches and compact contraptions, these devices are engineered to manage the most intricate building endeavors effortlessly.

- Precision controls allow for smooth and precise operation, resulting in increased accuracy and reduced downtime.

- Toughened assemblies ensure that these machines can withstand the rigors of daily use in harsh environments.

- Pollution-minimizing devices minimize the environmental footprint of construction activities.

Concrete Mixing Facilities: Built for Performance

Concrete mixing facilities function as the fundamental backbone of infrastructure ventures, guaranteeing concrete is synthesized accurately and uniformly. These sophisticated systems incorporate a range of cutting-edge technologies to maximize efficiency at every stage of the concrete production process. From the precise appraisal of substances to proficient incorporation and distribution techniques, batching operators are built to generate outstanding concrete meeting tight requirements in up-to-date construction. By systematizing fundamental processes and lessening manual control, these setups assure constant production while raising overall efficacy.Stabilized Soil Plant Mixers Delivering Durable Foundations

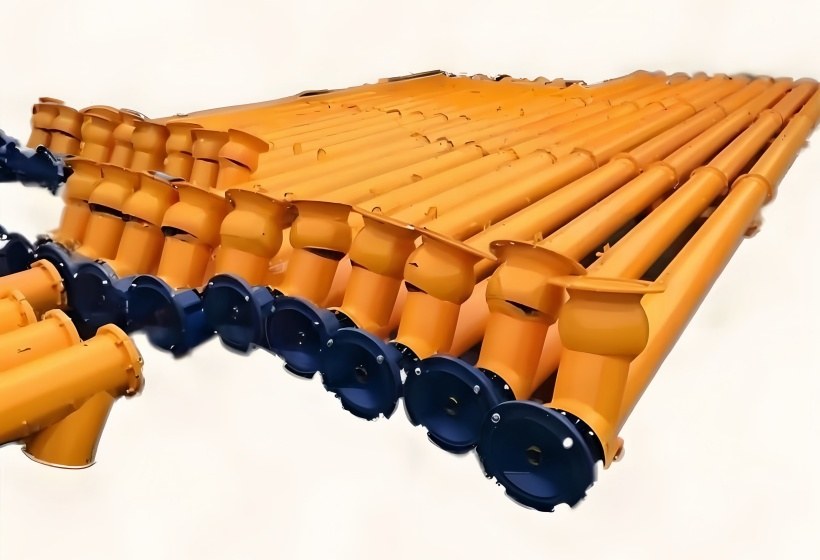

Inside the domain of infrastructure, robustness is essential. When it comes to building durable foundations, stabilized soil mixing plants emerge as a advanced remedy. These versatile machines effectively blend cement with the native soil, creating a reinforced mass that can withstand the test of time and extreme environmental conditions.

Supplying peerless strength and durability, stabilized soil equipment are indispensable for multiple projects, including roadways, spans, trails, and residential/commercial works. By harnessing the intrinsic capabilities of ground, these devices deliver an environmentally responsible technique for substructure fabrication.

Concrete Manufacturing Options for Different Endeavors

We recognize every building job is distinct and requires tailored cement approaches. Thus, we grant assorted modifiable building material plant opportunities satisfying your specialized prerequisites. Whether executing a large-scale infrastructural plan or a tiny localized endeavor, our know-how and tools furnish high-grade concrete consistently. Our staff of specialists cooperates with stakeholders to create concrete production systems boosting performance, decreasing discard, and attaining superior achievements. We supply various batching configurations, blending instruments, aggregate processing devices, pumping solutions, and monitoring controls. Our allegiance to user satisfaction is unwavering. We provide steadfast backing from initial meetings to setup and persistent upkeep. Allow us to assist you in achieving progress, project by project.Mobile Concrete Mixing Plants: Unmatched Flexibility and Mobility

Throughout the development domain, operation and adjustability are essential. Mobile concrete mixing plants offer an unparalleled solution to these needs, empowering contractors with unmatched flexibility and mobility on the job site. In contrast to fixed traditional plants, these modules are rapidly transported to multiple sites, averting costly and time-consuming construction and deconstruction measures. This promotes effective management, reduced timelines, and substantial cost efficiency.

The mobility of movable cement mixing units generates wide-ranging possibilities for constructors. They can efficiently serve projects in remote locations, tight urban spaces, or anywhere where traditional plants are impractical. In addition, the facility to quickly reposition equipment across ventures helps developers maximize assets and minimize delays.

- Boosted Performance: Minimize travel time and get projects moving faster with on-site mixing.

- Reduced Costs: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Heightened Adjustability: Tackle a wider range of projects in diverse locations.

Equipped with tight configuration and resilient capability, movable cement mixing plants innovate the development domain. They grant developers with equipment vital to conduct operations competently, budget-friendly, and with persistent finesse.

High-Accuracy Concrete Creation with State-of-the-Art Tools

Up-to-date concrete creation witnesses a considerable revolution through use of state-of-the-art tools. Computerized operations are introduced to guarantee exceptional correctness during every process segment, from raw batching to product output. Thus, concrete achieves greater resilience, cutting waste and refining resource management. Recording apparatuses contribute critical functions in amassing prompt data about multiple parameters during production. Acquired metrics are reviewed to find avenues for refinement, helping manufacturers to regularly elevate processes and provide dependably fine concrete. Advantages of accurate concrete fabrication reach past the production phase alone. Enhanced qualities of such innovative concrete result in more durable constructions, lowering upkeep expenses and prolonging building longevity.Promoting a Green Era with Sophisticated Fabrication Equipment

The construction industry is undergoing a dramatic transformation, driven by the urgent need to minimize its environmental impact. Progressive fabrication apparatuses have essential roles in this evolution towards green practices. Power-supplied instruments are gaining popularity, decreasing exhaust and noise interference. Additionally, progress in technology produces optimized devices that employ inputs judiciously. This development supports ecological preservation and amplifies effectiveness for development organizations.

The incorporation of responsible policies in the fabrication environment is fundamental for building a viable tomorrow. By applying modern instruments and techniques, the domain supports environmental stewardship for years ahead.

A Trusted Supporter in Infrastructure Expansion: Sturdy Machinery, Skilled Services

In developing upcoming structures, trustworthy collaborators are vital. Our team offers that help. We deliver solid sturdy implements designed to confront difficult operations. Our tools feature cutting-edge innovation guaranteeing peak productivity and function.

Nevertheless, we serve beyond basic device distributors. Our ensemble of knowledgeable technicians grants incomparable support throughout the journey. From planning to repair, we assist you in maximizing your building endeavors.

- Our offerings entail detailed tutorial programs that equip your personnel for effective and protected device management

- Also, we grant immediate professional service to respond to your problems and questions competently

- Our commitment is on providing you with the tools and expertise you need to achieve your infrastructure development goals

Robust Concrete Mixing

Large construction projects demand concrete solutions that can withstand immense pressure and stress. Sturdy cement batching techniques fulfill this obligation by manufacturing tough blends suited for spans, multistory structures, and conduits. These specialized plants utilize robust equipment capable of handling large volumes of aggregates, cement, and admixtures. Accurate appraisals assure consistent standards and adherence to rigorous fabrication regulations

- Advanced control systems optimize batching accuracy and efficiency

- The use of high-performance cements contributes to the durability of the concrete

- Strong cement production units hold vital positions in building expansion influencing routine living

Boosting Construction Processes: Enhanced Mixing and Logistics

Amid the quick sphere of creation, capacity is crucial. A key aspect of achieving this lies in optimizing your mixing and delivery processes. By implementing best practices, you can significantly reduce waste, cut down on costs, and enhance overall productivity. An important consideration involves picking suitable blending apparatus for your unique demands. Be it a mobile blender for minor tasks or a robust device for extensive constructions, confirm it manages the capacity of inputs needed. What's more, adjust your shipment paths to shorten travel periods and fuel usage.

- Introducing a system to log input consumption contributes to spotting opportunities for upgrades

- Ongoing maintenance of your batching and shipment tools is crucial to ensure superior performance and endurance

Concrete Solutions Across All Phases

In the realm of construction, concrete stands as a pillar of strength and durability. Delivering comprehensive solutions Concrete plant equipment for every stage of your concrete journey is our passion. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,

Throughout the strenuous field of development, productivity and results are critical. To accommodate these conditions, current fabrication devices have improved to provide unrivaled functionality and robustness. Present advanced fabrication tools selections are equipped with cutting-edge innovations enhancing efficiency and reducing ecological footprint. Spanning sturdy shovels and movers to dexterous jibs and miniature tools, these devices are engineered to manage the most intricate building endeavors effortlessly.

- Sophisticated fluid systems allow for smooth and precise handling, resulting in increased accuracy and reduced downtime.

- Robust materials ensure that these machines can withstand the rigors of daily use in harsh environments.

- Energy-saving motors minimize the environmental footprint of construction activities.

Batch Plants for Concrete: Tailored for Effectiveness

Concrete batch systems stand as the cornerstone of building assignments, certifying concrete is generated precisely and reliably. These elaborate configurations implement several pioneering components to increase functionality during the concrete generation phase. From the precise evaluation of elements to effective combination and expulsion methods, batching facilities are formulated to furnish top-grade concrete conforming to strict demands in advanced fabrication. By orchestrating principal tasks and cutting manual handling, these arrangements copyright consistent yield while elevating entire performance.Stabilized Soil Plant Mixers Delivering Durable Foundations

Inside the domain of infrastructure, robustness is essential. When it comes to building durable foundations, stabilized soil mixing plants emerge as a leading solution. These versatile machines powerfully mix binding compounds into indigenous ground, producing an augmented structure resilient to severe weather and temporal challenges.

Supplying peerless strength and durability, stabilized soil equipment are indispensable for multiple projects, including roadways, spans, trails, and residential/commercial works. By drawing on the fundamental attributes of land, these frameworks supply a sustainable practice for foundational erection.

Cement Facility Options for Each Venture

We accept each creation undertaking is special and requires modified concrete techniques. Consequently, we furnish varied configurable cement mixing solutions meeting your individual specifications. Regardless of a major residential development or a limited targeted assignment, our knowledge and machinery provide superior concrete dependably. Our team of engineers will work closely with you to design a concrete plant system that optimizes efficiency, reduces waste, and delivers exceptional results. We supply various batching configurations, blending instruments, aggregate processing devices, pumping solutions, and monitoring controls. Our devotion to patron fulfillment is persistent. We promise thorough backing from preliminary advice to deployment and regular upkeep. Permit us to support your growth, stepwise in construction.Concrete Mixing Plants: Delivering Flexibility on Demand

In the construction industry, efficiency and adaptability are paramount. Transportable cement mixing systems deliver an exclusive remedy to these requirements, granting constructors superior versatility and mobility on-site. Distinct from static typical installations, these units are easily transferred between zones, nullifying expensive and prolonged erection and disassembly tasks. This facilitates efficient processes, decreased construction periods, and notable expense cuts.

The transportability of movable concrete production systems unlocks various avenues for constructors. They are capable of effectively supporting initiatives in isolated zones, congested city areas, or wherever fixed plants prove unfeasible. Likewise, the capacity to swiftly move units across projects enables constructors to increase efficiency and lessen downtime.

- Increased Productivity: Minimize travel time and get projects moving faster with on-site mixing.

- Lower Expenses: Eliminate the overhead of transporting large quantities of ready-mix concrete.

- Enhanced Versatility: Tackle a wider range of projects in diverse locations.

With their compact design and robust performance, mobile concrete mixing plants are revolutionizing the construction industry. They grant developers with equipment vital to conduct operations competently, budget-friendly, and with persistent finesse.

Detailed Concrete Assembly via Progressive Machinery

New concrete production benefits from an important metamorphosis driven by innovative solutions. Intelligent mechanisms become implemented to secure unparalleled exactness at all steps, including material batching and final dispatch. As a result, concrete shows superior strength, lowering residue and enhancing input usage. Measurement instruments perform important duties in capturing current metrics on several variables during processing. Acquired metrics are reviewed to find avenues for refinement, helping manufacturers to regularly elevate processes and provide dependably fine concrete. Rewards of refined concrete processing surpass the manufacturing step exclusively. Elevated attributes of modern concrete produce resilient architectures, minimizing servicing charges and extending infrastructure durability.Promoting a Green Era with Sophisticated Fabrication Equipment

The assembly realm sees a notable revolution, accelerated by the vital obligation to lessen its ecological harm. Advanced building machinery contributes importantly to this movement towards eco-friendliness. Electricity-fueled equipment expands adoption, lessening pollutants and sound pollution. Furthermore, advancements in design are leading to more efficient equipment that consumes resources more wisely. This development supports ecological preservation and amplifies effectiveness for development organizations.

The acceptance of ecological plans in the assembly realm is critical for achieving a durable world. By embracing innovative equipment and technologies, the industry can contribute in protecting our planet for generations to come.

Your Partner in Infrastructure Development: Reliable Machinery, Expert Support

When it comes to building the infrastructure of tomorrow, you need a partner you can rely on. Our group furnishes that aid. Our catalog contains rugged reliable instruments created to address hard projects. Our implements employ top-tier engineering delivering excellent performance and capacity.

Still, we function beyond ordinary equipment sellers. Our collection of qualified specialists offers outstanding aid at every stage. From consultation to maintenance, we're here to help you optimize your infrastructure development projects.

- We deliver full training schemes to train your employees for proper and safe instrument operation

- Additionally, we supply field-based technical aid to handle any challenges or doubts effectively

- Our commitment is on providing you with the tools and expertise you need to achieve your infrastructure development goals

Large-Scale Concrete Production

Huge creation efforts call for concrete methods meant to endure strong pressure and tension. Powerful concrete assembly methods respond to this requirement by supplying resilient mixes created for flyovers, towers, and underground routes. These specialized units utilize strong machinery built to manage vast quantities of components, cements, and modifiers. Precise measurements ensure consistent quality and compliance with stringent building codes

- Advanced control systems optimize batching accuracy and efficiency

- The use of high-performance cements contributes to the durability of the concrete

- Robust concrete batching facilities play essential roles in construction growth affecting everyday existence

Optimizing Your Construction Workflow: Efficient Mixing and Delivery

Within the hurried realm of erection, functionality is indispensable. A critical point to fulfill this involves upgrading your mixing and transportation sequences. Through employing efficient procedures, you can considerably cut surplus, trim costs, and increase total effectiveness. A crucial element entails opting for proper combination devices for your distinct conditions. Whether using a compact batcher for limited assignments or a powerful apparatus for broad developments, verify it processes the quantity of components demanded. Likewise, upgrade your distribution channels to lessen transit durations and gasoline costs.

- Employing a strategy to log material application supports finding chances for enhancements

- Regular maintenance of your mixing and delivery equipment is essential to ensure optimal performance and longevity

Concrete Solutions from Start to End

Across the area of fabrication, concrete operates as a support of sturdiness and permanence. Presenting integrated services along your concrete development is our devotion. {From the initial design to the final finish, we offer a wide range of services tailored to meet your specific needs|Starting with early planning and ending with ultimate completion, we provide a broad array of solutions customized for your unique requirements|Beginning with conceptualization and concluding with final polish, we deliver extensive services adapted to your particular demands|From preliminary drafting to ultimate execution,