Gaining top-notch construction consequences depends on dedicated know-how along with high-tech techniques. Here lies the place where the professional group including skilled technicians combined with advanced CNC systems operate. This organization deliver a inclusive scope of exact CNC engineering functions to satisfy the broad wants of industries. Ranging from elaborate drafts to multifaceted fabrication runs, we focus on delivering unparalleled effects that outperform standards.

- The team delivers a wide-ranging set of machining methods, comprising cutting, boring, boring, and additional.

- Using the state-of-the-art CNC equipment, we deliver truthfulness, dependability, and competence.

- We collaborate with customers to meet their individual needs and offer tailored options.

Regardless of whether you want prototype machining or commercial production, our detailed CNC processing solutions are engineered to optimize your manufacturing approach. Reach out now to explore your project and discover how we assist in realizing your ideas.

Custom CNC Milling and Turning Solutions

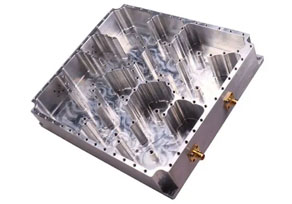

In the realm of precision manufacturing, tailorable CNC engineering strategies have become indispensable tools for crafting intricate components with unexcelled rigor. If seeking bulk manufacturing processes or individualized prototypes, these advanced machining processes offer a inclusive package of services to respond to your exact standards. Involving aluminum mixtures, stainless alloys, and further, our qualified engineers employ state-of-the-art CNC equipment to construct accurately measured parts that satisfy firm technical guidelines. We persistently ensure top quality, confirming every element transcends forecasts and furthers your goals.

Outstanding CNC Element Fabrication

CNC fabrication provides unmatched exactness and correctness, defining it as the foremost way to produce prime parts. Encompassing sophisticated drafts to broad production series, CNC instruments can produce components with exceptional detail.

The adaptability of CNC machining allows for the fabrication of parts from a wide range of elements, including metals, plastics, and composites. Through employing CAD technology, engineers can create complex geometries and intricate features with ease. This secures that the final product meets the exact specifications required for optimal performance.

CNC parts fabrication is a highly efficient process, reducing lead times and accelerating production workflows. The instrumentation inherent in CNC machining minimizes human error and ensures consistent precision across all parts produced.

CNC Machining for Prototypes and Production

CNC machining offers a versatile dynamic solution for both prototyping and full-scale production runs. Its ability to precisely fabricate parts from a variety of materials makes it ideal for creating accurate replicas during the design phase. As production scales up, CNC machining can consistently manufacture high-standard components meeting strict tolerances. This process involves using computer-aided designs (CAD) to generate toolpaths that guide a CNC machine to cut and shape materials, resulting in intricate and complex parts for diverse industries.

Skilled CNC Programming and Design

When it comes to high-precision manufacturing, correct CNC programming and design are essential. A seasoned expert in this field possesses a deep understanding of CAD/CAM software, machining principles, and material properties. They can translate complex designs into detailed toolpaths, ensuring smooth and efficient production processes. In addition, skilled CNC programmers customize cutting parameters to achieve the desired surface finish, tolerances, and overall quality.

- In conclusion, their expertise leads to cost-effective manufacturing, reduced scrap rates, and enhanced product reliability.

From prototyping to large-scale production runs, masterful CNC programming and design assist businesses to achieve their manufacturing goals with precision and efficiency.

Rapid CNC Machining for Fast Turnaround

In today's challenging manufacturing landscape, speed is fundamental. Customers require faster turnaround times for their orders, and businesses need to deliver. This is where rapid CNC machining comes in. Rapid CNC machining leverages high-speed cutting tools and advanced software to fabricate parts with impressive speed and accuracy. With minimal setup times and refined processes, businesses can greatly reduce lead times, meet demanding deadlines, and amplify their overall production efficiency.

Our Broad Range Of Materials And Capabilities

We deploy a multifaceted range of materials to support your specialized needs. From customary ingredients to progressive methods, our personnel is capable to control a vast spectrum of projects.

- What's more, we possess a ample proficiency that empowers us to supply bespoke solutions.

Competitive CNC Machining Pricing

Securing advantageous pricing for your CNC machining projects is crucial to boosting profitability and remaining ahead in the market. Utilizing a strategic approach, you can negotiate the best possible rates without reducing on quality. A key factor is meticulous research into sundry CNC machining shops and reviewing their pricing structures, turnaround times, and strengths. Don't hesitate to solicit quotes from multiple vendors, presenting clear specifications for your project. Remember, honesty is vital throughout the process, as it encourages building strong relationships with your chosen machining partners.

Stable and Faultless CNC Manufacturing

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone of precision and efficiency. A robust CNC system, characterized by its high-tech software and durable hardware, empowers manufacturers to achieve superior levels of accuracy and repeatability in their production processes. This unwavering rigor is essential for crafting complex components across a wide range of industries, from aerospace and automotive to medical devices and electronics. The ability to consistently produce parts with tight tolerances affirms optimal performance, longevity, and safety. To harness the full potential of CNC manufacturing, it's crucial to invest in robust machine tools and collaborate with skilled engineers who can optimize programs for peak capability.

All-Inclusive Service CNC Machining Center

A state-of-the-art full-service CNC machining center provides a wide variety of fabrication solutions. These centers feature advanced computer numerical control (CNC) tools capable of precisely producing components from diverse inputs such as alloys. From prototyping to finishing, a full-service CNC machining center offers adapted solutions addressing the unique requirements of various industries.

- Areas utilizing full-service CNC machining centers include industrial and household goods manufacturing.

- The strengths of utilizing a full-service CNC machining center consist of consistency, fast production, and price advantage.

The Expert Support in Precision CNC Solutions

When exactness prevails, you need a partner who understands the requirements of your projects. We are your trusted supplier for extensive CNC machining capabilities. Our team leverage state-of-the-art equipment and reliable techniques to deliver exceptional results that fulfill your specifications. From prototyping to production runs, we are committed to providing trustworthy service and unwavering customer support every step of the way.

Obtaining outstanding manufacturing products needs qualified knowledge combined with up-to-date tools. It stands as the point where the dedicated team made up of capable operators along with leading-edge CNC machinery engage. This firm provide a broad assortment of precision CNC manufacturing support to handle the varied necessities of domains. From complex mockups to sophisticated manufacturing runs, we dedicate ourselves to delivering outstanding consequences that outdo expectations.

- We provide a extensive array of engineering approaches, including milling, milling, turning, and additional.

- Using the state-of-the-art CNC machinery, we assure accuracy, repeatability, and productivity.

- Our skilled machinists coordinate with stakeholders to satisfy their unique criteria and furnish modified remedies.

In case you look for sample engineering or wide-scale production, our fine CNC engineering support are built to refine your engineering operation. Speak with us today about your project and understand how we bring your dream to life.

Adapted CNC Manufacturing Options

Amid the area of meticulous construction, adaptable CNC fabrication services have become indispensable tools for assembling delicate items with unrivaled correctness. When requiring extensive production series or specialized concepts, these progressive engineering practices supply a broad spectrum of options to satisfy your rigorous specifications. Including aluminum mixes, stainless metals, and others, our knowledgeable artisans apply cutting-edge CNC machinery to develop geometrically exact parts that satisfy firm technical guidelines. We persistently ensure top quality, confirming every element transcends forecasts and furthers your goals.

Outstanding CNC Element Fabrication

CNC machining offers unparalleled accuracy and precision, identifying it as the main system for assembling outstanding modules. Spanning complex models to extensive manufacturing batches, CNC apparatus can produce components with exceptional accuracy.

The flexibility of CNC machining allows for the fabrication of parts from a wide range of substances, including metals, plastics, and composites. Utilizing computer-based design applications, engineers can create complex geometries and intricate features with ease. This guarantees that the final product meets the exact specifications required for optimal performance.

CNC parts fabrication is a highly efficient process, reducing lead times and boosting production workflows. The electrification inherent in CNC machining minimizes human error and ensures consistent quality across all parts produced.

CNC Machining for Prototypes and Production

CNC machining offers a versatile efficient solution for both prototyping and full-scale production runs. Its ability to precisely fabricate parts from a variety of materials makes it ideal for creating accurate exemplars during the design phase. As production scales up, CNC machining can consistently manufacture high-caliber components meeting strict tolerances. This process involves using computer-aided designs (CAD) to generate toolpaths that guide a CNC machine to cut and shape materials, resulting in intricate and complex parts for variegated industries.

Expert CNC Programming and Design

When it comes to high-precision manufacturing, precise CNC programming and design are essential. A seasoned expert in this field possesses a deep understanding of CAD/CAM software, machining principles, and material properties. They can translate complex designs into detailed toolpaths, ensuring smooth and efficient production processes. Besides, skilled CNC programmers enhance cutting parameters to achieve the desired surface finish, tolerances, and overall quality.

- Accordingly, their expertise leads to cost-effective manufacturing, reduced scrap rates, and enhanced product reliability.

From prototyping to large-scale production runs, distinguished CNC programming and design promote businesses to achieve their manufacturing goals with precision and efficiency.

Rapid CNC Machining for Fast Turnaround

In today's competitive manufacturing landscape, speed is critical. Customers require rapid turnaround times for their components, and businesses need to deliver. This is where rapid CNC machining comes in. Rapid CNC machining leverages high-speed cutting tools and advanced software to create parts with extraordinary speed and accuracy. With minimal setup times and enhanced processes, businesses can markedly reduce lead times, meet demanding deadlines, and expand their overall production efficiency.

Our Inclusive Range Of Materials And Capabilities

We deploy a ample range of materials to support your tailored needs. From typical items to up-to-date tools, our workforce is fitted to execute a inclusive spectrum of projects.

- What's more, we possess a ample proficiency that empowers us to extend bespoke solutions.

Competitive CNC Machining Pricing

Securing advantageous pricing for your CNC machining projects is crucial to boosting profitability and remaining ahead in the market. Leveraging a strategic approach, you can negotiate the best possible rates without reducing on quality. A key factor is meticulous research into several CNC machining shops and assessing their pricing structures, turnaround times, and expertise. Don't hesitate to ask for quotes from multiple vendors, providing clear specifications for your project. Remember, directness is vital throughout the process, as it stimulates building strong relationships with your chosen machining partners.

Dependable and Dependable CNC Manufacturing

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone of precision and efficiency. A robust CNC system, characterized by its sophisticated software and robust hardware, empowers manufacturers to achieve impressive levels of accuracy and repeatability in their production processes. This unwavering correctness is essential for crafting complex components across a wide range of industries, from aerospace and automotive to medical devices and electronics. The ability to consistently produce parts with tight tolerances guarantees optimal performance, longevity, and safety. To harness the full potential of CNC manufacturing, it's crucial to invest in steady machine tools and collaborate with skilled engineers who can refine programs for peak performance.

Complete Service CNC Machining Center

A top-tier full-service CNC machining center provides a wide spectrum of fabrication services. These centers house advanced computer numerical control (CNC) devices capable of precisely fabricating components from diverse materials such as ceramics. From planning to finishing, a full-service CNC machining center offers adapted solutions satisfying the unique parameters of various industries.

- Markets benefiting full-service CNC machining centers include manufacturing and commercial goods manufacturing.

- The advantages of utilizing a full-service CNC machining center feature accuracy, swift processing, and affordability.

Your Partner in Precision CNC Solutions

When precision is paramount, you need a partner who understands the intricacies of your projects. We are your trusted consultant for a wide range of CNC machining options. Our experts leverage state-of-the-art equipment and validated techniques to deliver high-quality results that outperform your specifications. From prototyping to production runs, we are committed to providing trustworthy service and unwavering customer support every step of the way.

cnc machining services