Comprehending Pigging Processes

Elaborate Hydrocarbon Pipeline Maintenance Notions:

Industrial Pipe Cleaning embodies a exceptionally powerful strategy chiefly useful within the oil and gas arenas, yet also displaying multifaceted adaptations in the aquatic pipeline configurations. In essence, it requires deploying a device termed a "pig," typically cylindrical in contour, into a pipeline to sweep it. These mechanisms are multifunctional, handling duties such as eradicating deposits including wax, scale, and corrosion, verifying pipeline health, and boosting stream effectiveness. Unlike conventional pipeline upkeep approaches, pigging minimizes downtime, softens energy utilization, and extends the duration of the pipeline, making it an value-driven and environmentally ethical practice. The procedure can be automated or manually handled, depending on the definite pipeline and required outcome.

Assessing Flow Cleaning Processes:

Pipeline Inspection steps offer a highly efficient approach for keeping pipelines, especially within the refined fuel and gas sector. Central to this is the pig – also called a scraper – a strong, often cylindrical, implement propelled by pressure differentials. Initially, a “launch station” thrusts the pig into the pipeline using a sequence of valves to build a pressure shift. This launch activation sets the pig moving at a steady rate, influenced by pressure evenness and pipeline traits. While traveling, the pig scrubs off deposits such as wax, scale, corrosion byproducts, and hydrate formations that hinder flow performance and may cause pipeline stoppages. Subsequently, pipeline pressure reinstates behind the pig, enabling continued passage. At the end, a “receiving station” grabs the pig, usually incorporating a pig receiver that isolates the pig for inspection, and refurbishment if needed. The entire routine is diligently controlled to ensure pipeline durability and peak efficiency.

Pigging Essentials, Components, and Purposes

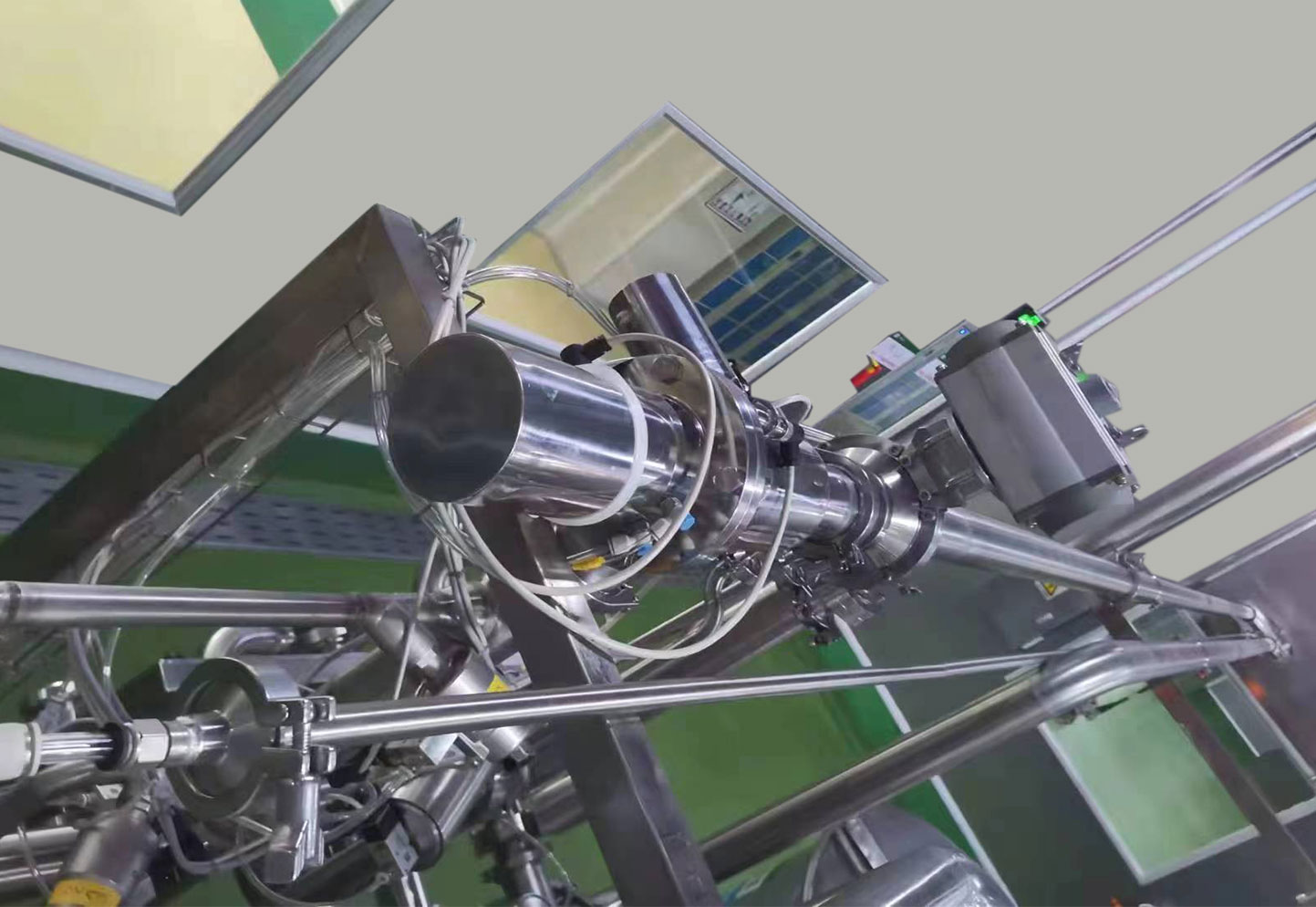

Pipe Scraping acts as an vital process for preserving pipeline integrity and operation across diverse spheres. The fundamental principle involves a specialized device named a "pig" traveling through the system to clean and inspect its internal surface. Such pigs, generally cylindrical in configuration, are propelled by pressure variations, usually by injecting fluid leading the pig and drawing it out in the wake of it. A typical pigging setup features essential sections, such as a launch station, receiver station, the pig itself – customizable for designated duties like cleaning, gauging, or inspecting – and a control board. Applications reach wide spectra, from the petroleum and gas field removing deposits and ensuring stable flow, to the liquid sector for cleaning water mains, and chemicals segment for transporting and maintaining product lines. Efficient pigging methods minimize operational outlays, limit downtime, and importantly, enhance safer and more reliable network maintenance.

This Practice of Duct Maintaining and Review

The scouring methodology, a vital aspect of maintaining pipe reliability, is a surprisingly complex engineering accomplishment. It fundamentally involves inserting a apparatus called a “pig” into the tube and pushing it by compressed vapor. This scraper removes contaminants such as decay found on internal walls, enhancing flow efficiency and deterring costly blockages. Beyond basic cleaning, modern pigs are outfitted with progressive measuring devices for detailed internal examination. These contraptions detect defects, measure wall thickness, and spot diverse anomalies, delivering critical data for predictive upkeep and proactive repairs, thus minimizing risk and prolonging pipeline working life. This innovation merges mechanical creativity with data inspection to bolster sturdy infrastructure longevity.

Fundamentals of Pigging:

Pipeline Maintenance, a indispensable part of pipeline management, comprises employing a mechanism known as a “pig” to maintain pipelines. This method holds extensive use across domains such as mineral oil, hydrological supply, and process fields. The pros include enhanced flow throughput, decreased product drainage, preserved pipeline robustness, and reduced operational expenditures. Various types of pigs exist, typically grouped as cleaning pigs that remove deposits, inspection pigs equipped with sensors to spot defects, and dual pigs for flexible implementation. Proper pig choice requires evaluating duct fabric, diameter, fluid characteristics, and anticipated obstructions. Meticulous pig selection is vital to maximize outcomes and minimize damage.

Understanding Pigging Technology Execution

The comprehensive review of pigging mechanism role demonstrates a surprisingly intricate sequence of events. The rudimentary principle propels a ‘pig’ – a bespoke device – through a conduit via a positive displacement instrument. This propelling serves multiple purposes, including debris purging, pipeline renewal of integrity, and operation maximization. The entire approach is carefully directed, with influencing factors including pig rate, launch and receiving impact, along with pig material. These elements play a vital role in realizing the intended outcome. Additionally, innovative procedures integrate sophisticated supervising mechanisms enabling real-time assessment and fine-tuning of pigging operations, substantially heightening performance and mitigating downtime.

Pigging Design: Crucial Concerns and Prime Procedures

Powerful line pigging blueprint demands attentive evaluation of multiple essential aspects. Choosing the ideal pig class is paramount, with factors like duct diameter, material suitability, and nature of build-up to remove considered. A sturdy pigging system must incorporate comprehensive power drop monitoring to detect blockages or damage early. Additionally, introducing and acceptance locations must be optimally located to promote efficient pig movement and limit downtime. Routine checkup and review of the pigging system are essential to sustain optimum performance and prolong its active time. Finally, adherence to safety standards is mandatory, addressing potential hazards and securing the well-being of technicians.

Handling Pigging Process Complications and Effective Treatments

Preserving peak pigging capability often requires addressing unexpected obstacles. Power drops surpassing acceptable standards are a common concern, typically due to leaks in the duct or a partially blocked pig. Regular examination of fittings and connections, alongside pig tracking methods, helps largely mitigate this risk. Another usual problem is pig damage, often caused by abrasive environments or improper pig choice for the designated task. Employing durable pigs with suitable wear resistance and carefully analyzing pipeline characteristics before deployment are crucial preventative steps. Moreover, pig cycling complications, such as incomplete sweeps or jammed pigs, may arise from inaccurate launcher or receiver pressure or internal pig malfunctions. Timely maintenance and pressure tests of these units, plus using pig bypasses where feasible, significantly assist in maintaining dependable pigging operations. Finally, ensuring chemical agent compatibility during pig cleaning is vital to avoid pipeline material deterioration.

Pipe Soundness Support Through Pigging: Handling Corrosion and Fouling

Maintaining pipeline reliability is crucial within the hydrocarbon and gas fields, where pigging, alternatively known as pipeline inspection, plays a vital role. These intelligent units, propelled through ducts by pressure, meticulously remove contaminants and identify areas vulnerable to corrosion. Fouling, an accumulation of waxes, hydrates, and other residues, decreases performance and provokes operational challenges. Simultaneously, often-invisible corrosion undermines pipe walls, creating safety hazards and risks. Regular pigging programs—utilizing cleaning pigs and inspection gadgets—proactively address these concerns, extending asset operational lifetime and minimizing costly, potentially devastating failures. Advanced pigging technologies now incorporate highly sophisticated sensors capable of assessing wall thickness and detecting even minute defects.

Modern Pigging Instruments: High-tech Pigs and Insight Retrieval

The advancement of pipeline integrity management introduced a new era of elaborate pigging procedures, led by smart pigs and improved data collection capabilities. These sophisticated tools mark a major leap from traditional pigging, surpassing mere cleaning and debris removal. Modern intelligent pigs come with sensor arrays—including inline inspection tools for corrosion detection and geometric measurement—that continually gather data on pipeline condition. This information transmits real-time or post-run to surface hubs, where it undergoes rigorous analysis to identify risk points and drive proactive maintenance strategies. Furthermore, enhanced data management offers finer, actionable insights, enabling targeted repair efforts and trimming unplanned downtime. Some advanced setups integrate machine learning and algorithms to forecast failures and optimize pigging schedules for optimal efficiency. Incorporating these technologies remains vital to safeguard safety, dependability, and lifespan of key infrastructure assets across varied sectors.

Sustaining Pigging Practice Effectiveness

Routine handling method servicing is essentially vital to enhance best operation and prevent substantial interruptions. This incorporates periodic examinations of pig apparatus, including cup and wear ring state, bushing condition, and launcher capability. Moreover, diligent and appropriate handling of the pig following each run is crucial. Neglect of these vital facets could provoke increased fluid losses, damaged pipeline structures, and eventual operational breakdowns. Consequently, a proactive maintenance schedule—a detailed, planned regimen—is strongly recommended to guarantee long-lasting dependability and extend the endurance of pigging systems.

Appreciate how pigging system works your time