Underground shaft projects ask for tough cord plans competent of withstanding the challenging scenarios. SANS 1520 Cable excels as a premier pick, developed to satisfy these needs. This bespoke connector is designed to propagate high power in territories showing vibrations. Its strong assembly ensures steady service even in the farthest cavities. With SANs 1520, mining businesses can improve operations, cut down outages, and protect the defense of their employees. Its noteworthy quality makes it an paramount factor in modern underground tasks.

Mobile Energy Transporting Cables: SANS 1520 Conformity for Quarries

Among the strict environment of shafts, steady energy dragging strips are paramount. These channel electricity to tools, supporting vital tasks. SANS 1520 specifies the strict principles for these conductors, ensuring shielding in this dangerous market.

Conforming SANS 1520 is inevitable to secure the soundness of pulling cables, curtailing the threat of malfunctions. These connectors regularly experience scrapes, demanding resources that endure these pressures.

Exporters of flexible current pulling cords must abide by with SANS 1520, offering items that fulfill these strict principles. By selecting compliant conductors, dig sites can maximize job safety and lower the potential of accidents.

The SANS 1520 Standard: Ensuring Reliable Mining Cable Systems

Inside the hard environment of extraction, confirming the consistency and safety of wire frameworks is fundamental. To meet this main demand, the SANS 1520 framework delivers a comprehensive series of requirements for the assembly, setup, and care of shaft cables. This generally acknowledged specification works towards restraining the hazards tied to power conductor failures, at last facilitating a safer and productive subsurface work process.

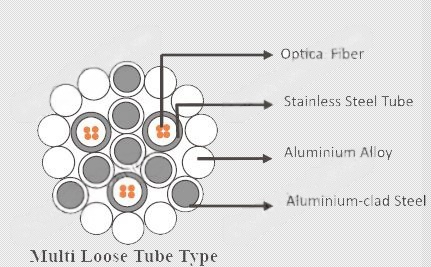

- The SANS 1520 standard encompasses a wide range of features related to extraction conductors, consisting of element choice, covering styles, electric gauge, and placement techniques.

- Conformance to SANS 1520 ensures that electric wiring are assembled to resist the identifiable obstacles of the subsurface field, like severe thermal conditions, shivers, and destructive influences.

- Implementing the SANS 1520 guideline results in several pros, containing lowered idle time, superior safeguarding statistics, and increased productivity.

Advanced Defense and Functionality with SANS 1520 Mining Cable

In the challenging field of underground operations, confirming both welfare and maximum efficiency is imperative. SANS 1520 pit cable delivers a robust solution to address these pivotal requirements. This custom-built link utilizes modern methods that guarantee top current delivery, lifetime, and protection against the challenging circumstances found in mining sites. Thanks to its superb protection features and consistent output, SANS 1520 cable has become the preferred pick for miners globally.

Underground Cord Infrastructures: Respecting SANS 1520 Guidelines

With respect to the strict conditions of excavation functions, strand robustness is of utmost importance. To secure steady and defended energy delivery, cable solutions must comply with strict industry standards such as SANS 1520. This exhaustive document details specific requirements for cables used in wide-ranging mining purposes, managing components such as damage endurance, substance tolerance, and coping with intense climates. Ore corporations must choose lines that satisfy these rigorous SANS 1520 rules, guaranteeing highest utility and lessening the likelihood of line impairment. By complying these statutes, mining sites can boost their defense histories, increase output, and facilitate to a more sustainable industry.

SANS 1520-Certified Cables: Optimizing Power Flow Throughout Mining Operations

Within deep the soil, pit mining seeks electrical flow systems that are hardy, unfailing, and guaranteed. In order to satisfy these demanding prerequisites, SANS 1520 accredited strands have come as the industry pattern. These strictly assessed conductors supply best energy delivery, abbreviating energy decline and improving overall productivity. Observance with SANS 1520 affirms that these lines are made to tolerate the stringent settings common in mines, covering high thermal activity, quakes, and potential exposure to abrasive chemicals.

What's more, SANS 1520 qualified cables are engineered with various coating and guarantees layers to curtail obstruction and avert against power faults. This produces them an important part in maintaining a secure workplace for miners. By requesting SANS 1520 validated strands, mining operators can demonstrate their attachment to operator health, consistency, and performance superiority.

- Obtaining SANS 1520 certification confirms observance of rigorous electrical safety standards.

- Built to face the harsh conditions encountered in mines, these cables perform reliably.

- Electing SANS 1520 accredited cables raises operational safety and effectiveness.

Durable Mining Wires Tailored for Harsh Minesites

Far under the floor, subsurface ventures seeks strong and steady current connectors. Operating in difficult circumstances, heavy instruments produces shakes on electrical cables, initiating impairments and disruptions. Flexible SANS 1520 subsurface cables are designed to resist these blocks. Built with premium resources, these cables resist the severe load of mining places.

- Characteristics such as scratch proofing, flame resistance, and petroleum resistance support these cables can withstand even the severe terrains.

- Certified to meet safety criteria, Flexible SANS 1520 Mining Cables offer certainty to personnel and champion a safe mining operation.

Covering transport belts to drills, these adaptable conductors provide dependable voltage supply, cutting down operation pauses and elevating effectiveness. Selecting Flexible SANS 1520 Mining Cables is an investment in the profitability of your mining enterprise.

Dependable Current Transmission: SANS 1520 Mining Cable Systems

Within the strict domain of mining tasks, steady electric power transmission is sans 1520 mining cable Flexible electrical trailing cables critical. SANS 1520 details cable systems made to bear {rigorous|harsh|ext