Inside the realm of mechanical functions, safeguarding the robustness and capability of lines is required. Collection of contaminants within tubes can notably retard flow velocity, diminish manufacturing caliber, and elevate maintenance outlays. To manage these obstacles, line purification strategies have materialized as notably successful fixes for streamlined channel cleaning. A implement, essentially a tube-shaped mechanism, is driven through the pipe, competently scrubbing contaminations and securing superior capability

Conduit cleansing methods yield numerous positive points. They are adjustable, capable of sanitizing pipes of heterogeneous diameters and ingredients. Furthermore, they are efficient, fulfilling the operation in a moderately rapid duration. By slashing downtime and boosting pipeline functionality, pipeline cleaning systems support expenditure savings and heightened operational manufacturing

Hygiene Pigging Techniques:

Safeguarding pipeline purity is fundamental for supporting commodity integrity and value of transported items. Sanitary pigging technologies furnish a reliable way to fulfill this mission. Pigs, customized instruments, are fitted into pipelines to purify by eradicating residues and dirt

- Numerous forms of sanitary pigs are offered, each structured for specific cleaning jobs.

- These pigs are manufactured from compositions that comply with stringent cleanliness standards.

- Consistent sanitary pigging tasks boost preventing product impurity, increase pipeline service life, and augment complete performance.

Cutting-Edge Pigging Solutions for Enhanced Capability

pigging systemsInside the landscape of passage maintenance, cutting-edge pigging methods have arisen as a fundamental mechanism for providing maximum capability and conservation. These frontline systems utilize sophisticated designs and functions to effectively clean, inspect, and shield pipelines from deterioration. From intelligent pigs equipped with real-time assessment modules to customized pigging apparatus purposed for detailed tasks, development in this domain is persistently advancing frontiers. By embracing these innovations, personnel can materially upgrade pipeline reliability, reduce downtime, and improve operational productivity.

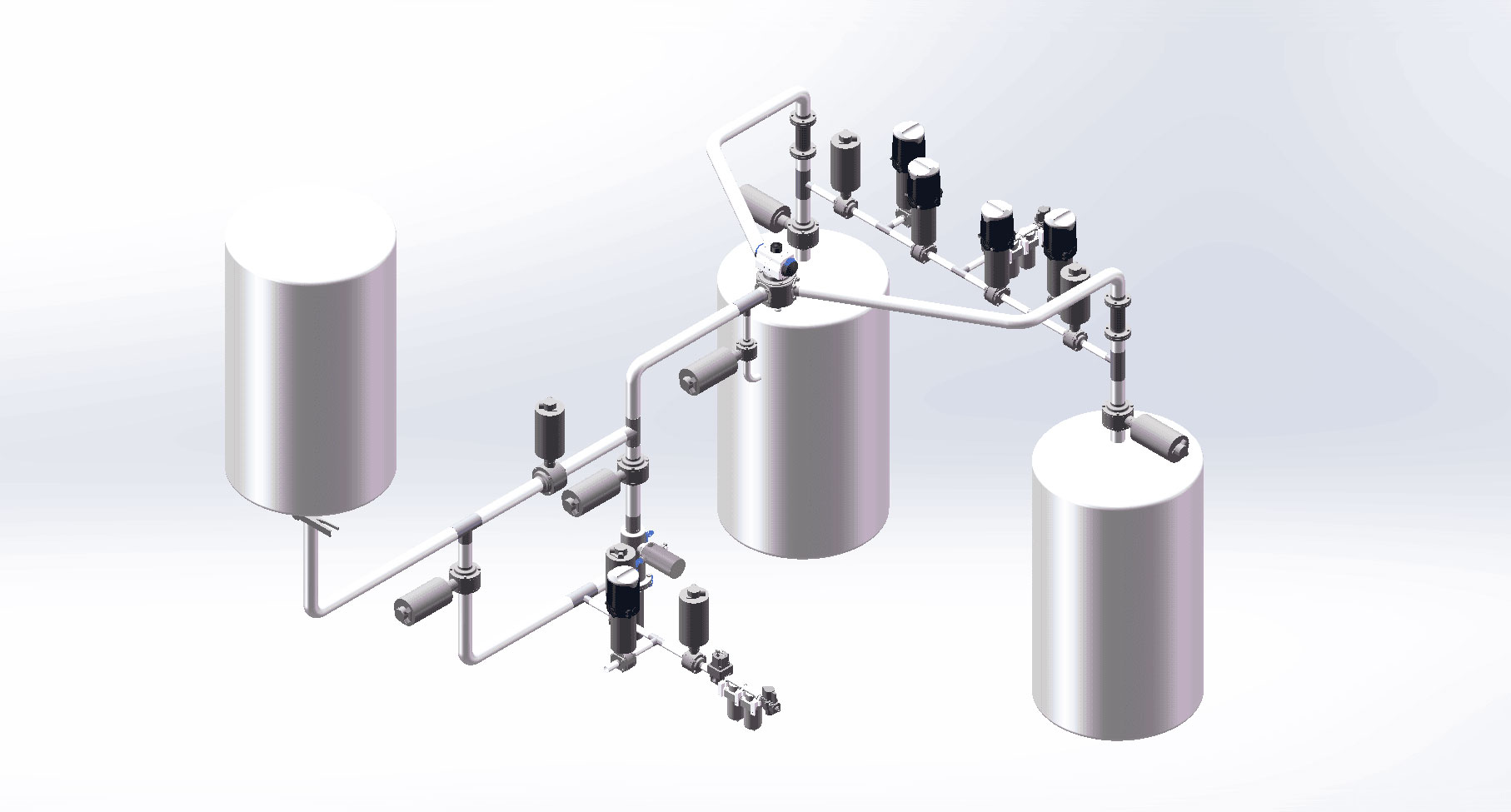

Far-reaching Pigging Plan Layout and Fitting

One comprehensive pigging system consists of a pivotal process for pipeline maintenance. This routine embraces the installation of tailored devices called pigs, which venture through pipes to sanitize, analyze, and secure their stability. The configuration underscores features such as pipeline scale, substance, pig category, and operational specifications. A meticulously structured system guarantees robust pigging functions while minimizing downtime and potential losses. Installation processes push for careful management, skilled technicians, and strict adherence to safety directives to secure a risk-free and positive result

Engineering Pigging Tools for Multifaceted Functions

Mechanical pigging equipment are indispensable components handed across a vast group of industries. These products assist risk-free and advanced washing, scrutiny, and preservation of passages and other cylindrical buildings. Pigging involves installing specialized contraptions known as pigs through pipes to handle different responsibilities. Common types of industrial pigging instruments comprehend cleaning pigs, inspection pigs, and delivery pigs. Cleaning pigs are designed to extract debris, build-up, and residues from pipelines. Inspection pigs are outfitted with instruments that obtain information about the circumstances of pipe walls. Transport pigs are applied to distribute fluids through pipelines. The use of industrial pigging products yields numerous positives, such as trimmed downtime, enhanced pipeline durability, and maximized operational productivity. These devices are universally instrumented in sectors such as oil and gas, water treatment, chemical production, and food manufacturing.In-Depth Insight into Pipeline Pigging

Pipeline pigging is an principal method used within the oil and gas sector to examine pipelines. This vital function consists of deploying tailored units, denoted as pigs, into the channel. Pigs are formed to advance through the length of the pipeline, performing various tasks.

Various categories of pigs are at one's fingertips, each customized for a individual target. Common roles of pipeline pigging invoke inspection for defects, cleaning, and protective layer application.

- Positive Outcomes of Pipeline Pigging

- Influences on Operational Efficiency

- Groups of Pipeline Pigs

Proven Sanitation with Pigging Processes

Pigging processes deliver a effective answer for ensuring sanitation inside conduits. These methods utilize custom-made pigs that move through the pipeline network, efficiently eradicating impurities. The practice is especially effective for domains that call for rigorous cleanliness standards. Pigging systems contribute a cost-saving and prompt approach for disinfecting conduits, minimizing the hazard of defilement.

Deciding on Pigging Instruments for Unique Demands

Pigging gear functions a key role in successful pipeline functioning. When electing pigging hardware, it is important to consider the specific criteria of your function. This requires assessing components such as pipeline dimension, flow rate, product designation, and servicing specifications.

Plenty of pigging models are offered, each developed for distinct reasons. For instance, some pigs are built for surveillance, while others are deployed for clearing dirt or partitioning product collections.

In addition, pigging tools constituents should be appropriate with the transferred liquid.

It is always preferred to seek advice from a technician in pigging systems to make certain that you pick the most correct device for your distinct expectations.

Pigging Systems - A Result-Oriented Approach

Pigging systems furnish a diverse variety of assets for fields focused on pipelines. By successfully cleaning and monitoring channel interiors, pigging systems enhance operational output and reduce maintenance charges.

A core advantage of pigging systems is their competence to wipe off buildup such as layering, debris, and oxidation products. This periodic upkeep supports easy pipeline movement and blocks costly downtime.

Also, pigging systems can be utilized to monitor the shape of pipelines, revealing potential defects before they amplify into extensive concerns. This anticipatory plan boosts to extend the lifespan of pipelines and reduce overall maintenance costs.

Supporting Hygiene in Pigging Activities

Sow farming practices substantially lean on appropriate hygiene regulations to diminish the passage of illness. Adopting rigorous hygiene standards maintains a sound habitat for pigs, thus generates augmented health outcomes and functionality.

Comprehensive cleaning and disinfection of premises is vital to reduce the growth of harmful pathogens. Adequate excrement management in addition acts a significant part in ensuring hygiene.

Moreover, {workers